Quick Enquiry

* fields are mandatory.

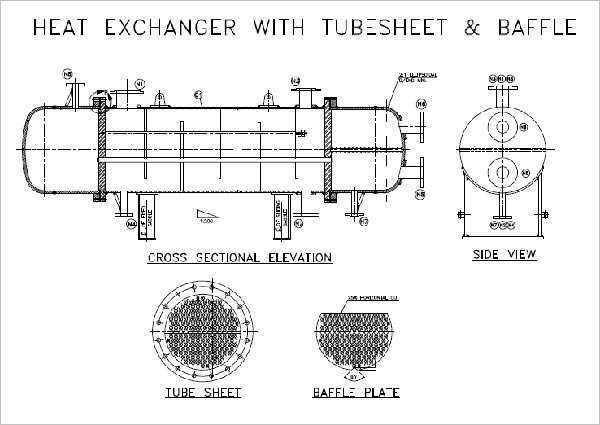

Shell & Tube Heat Exchanger

|

|

|

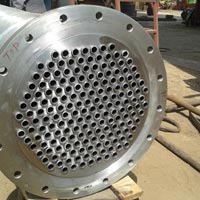

We are trusted in the industry for manufacturing and supplying the Shell & Tube Heat Exchangers that are used to condense the vapors leaving the top of a distillation column into liquid, by removing heat of vaporization. These Shell & Tube Heat Exchangers are fabricated using the top class materials such as Steel SS-316, SS-304, Mild Steel etc. We design and develop these Shell & Tube Heat Exchangers as per the industry norms to make them efficient enough to work under the most challenging conditions. Our Shell & Tube Heat Exchangers are available in 1 Sq. MT. to 60 Sq. MT. in size.

Applications

- Chemical Industry

- Food & Beverage Industry

- Bulk Drugs

- Fertilizers

- Pesticides

- Dyes

- Cosmetics Industry

- Petroleum

- Refineries

- Petrochemical Plants

- Natural Gas Processing

- Refrigeration

- Power Plants

- Space Heating

- Allied Industries

Used For : Transfer the heat to condensate vapours.

Sizes Available : 1 sq. mt. To 60 sq. mt. Size.

Raw Material Used : Mild Steel and Stainless Steel (SS-316, SS-304, Alloy-2205).

Price : Rs. 2 Lacs to 20 Lacs

Technical Detail: Shell and tube heat exchangers consist of a series of tubes. One set of these tubes contains the fluid that must be either heated or cooled. The second fluid runs over the tubes that are being heated or cooled so that it can either provide the heat or absorb the heat required. A set of tubes is called the tube bundle and can be made up of several types of tubes: plain, longitudinally finned etc. Shell and Tube heat exchangers are typically used for high pressure applications (with pressures greater than 30 bar and temperatures greater than 260oC.

Specifications

| Type | Shell Tube Heat Exchanger |

| Material | Gun Metal |

| Certification | CE Certified |

| Application | Oil Refineries |

| Weight | 100-1000kg |

| Color | Metallic |

| Voltage | 110V |

| Automatic Grade | Automatic |

| Power | 1-3kw |

| Warranty | 2 Years |

| Driven | Electric |

Graph